If you’re a kitchen contractor or homeowner who has tried to order cabinets for a remodeling project, it’s no surprise these days to see lead times of months instead of what used to be weeks. Why this big change? Over the past 18 months, the pandemic wreaked havoc up and down the supply chain for raw materials. Lockdowns led things off, leading to labor shortages and shipping problems that are still causing problems today.

The cabinet industry and other manufacturers have been working with government officials to address these supply chain issues. Still, the web of interdependency across all industries means that any solution will require slow and steady collaboration. There’s no quick fix even as demand for kitchen cabinets continues to rise.

How a raw materials supply chain works

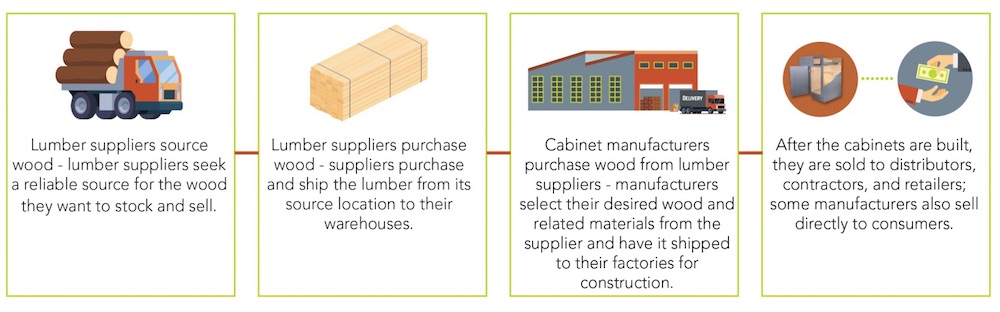

Whether we’re contractors or homeowners, most of us have had little reason to pay attention to how the finished products we purchase off the retail shelf or from a warehouse get there in the first place. The supply chain for raw materials has to connect four links before the final product is available for purchase and installation.

Steps in the supply chain of a kitchen cabinet

- Lumber suppliers source wood from a reliable source.

- Lumber suppliers purchase wood and ship the lumber from its source location to their warehouses.

- Cabinet manufacturers purchase wood from lumber suppliers and have it shipped to their factories for construction.

- After the cabinets are built, they are sold and shipped to contractors or directly to consumers.

At every point along the way, a shortage of some or all raw materials and/or labor or transportation will cause a delay at the next point in the chain.

What’s going on with the cabinet manufacturing supply chain today?

Economics 101 tells us that rising demand causes prices to go up too. A surge in demand has driven up the cost of raw materials for cabinets. With people at home during the previous year’s lockdowns, many homeowners decided to make changes to their living spaces, and kitchen remodels are consistently high on the priority list. If you look around, it seems like everyone is building or remodeling!

Employee shortages are another significant piece of the puzzle. There are employee shortages at shipping ports, transportation hubs, trucking companies, and factories. Demand means there’s plenty of work to do, but not enough of the right people – in the right places – to do the work.

Today, kitchen cabinet manufacturers must somehow solve the problem of more expensive materials and harder to procure, as well as a lack of workers. Some manufacturers have managed to mitigate shortages on the materials front by finding different suppliers, but high costs remain an issue.

Near the end of the chain, kitchen cabinet contractors experience a shortage of cabinet parts and longer lead times for delivery, making it challenging to complete a project on time. And homeowners are unhappy because their kitchen renovation, which would have taken approximately eight weeks total in 2019, could now take months just for the cabinets to arrive.

How cabinet manufacturers are navigating supply disruptions

Cabinet manufacturers faced drastic increases in the expense of importing materials. Swings in the supply and demand for shipping containers have caused shipping prices to rise. Most manufacturers have had to increase product costs or shipping fees as high as 20% to continue supplying products, switch to lower quality lumber and parts to keep costs down, or some have completely been unable to keep up with providing cabinets to their contractors.

Only cabinet suppliers with extensive manufacturing and warehousing capabilities or local sources for material have maintained strong inventory or production levels despite all the current industry challenges.